Application of Imaging for the study of Fabrics

In the manufacture of sterile coats for hospital use, particular importance is given to the choice of fabrics; the texture of the weaving and the characteristics of the yarn are important not only for the resistance of the product but also for their tendency to accumulate impurities which, even after careful cleaning, can contaminate sterile environments. The manufacture of coats, and in particular the sewing, can take place in a classical manner or with welds with hot glue, aimed to eliminate spaces and areas in which dirt and bacteria can accumulate.

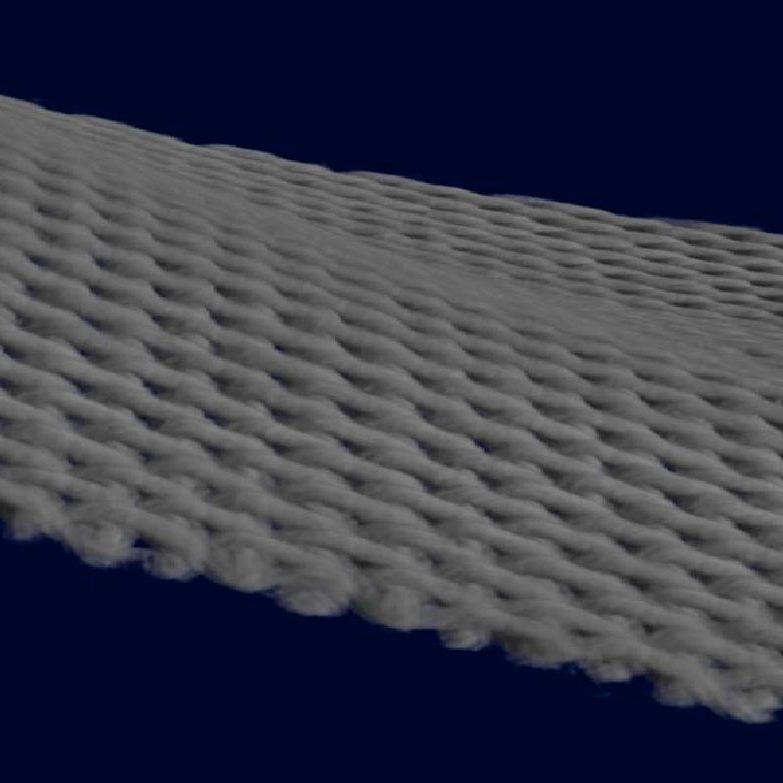

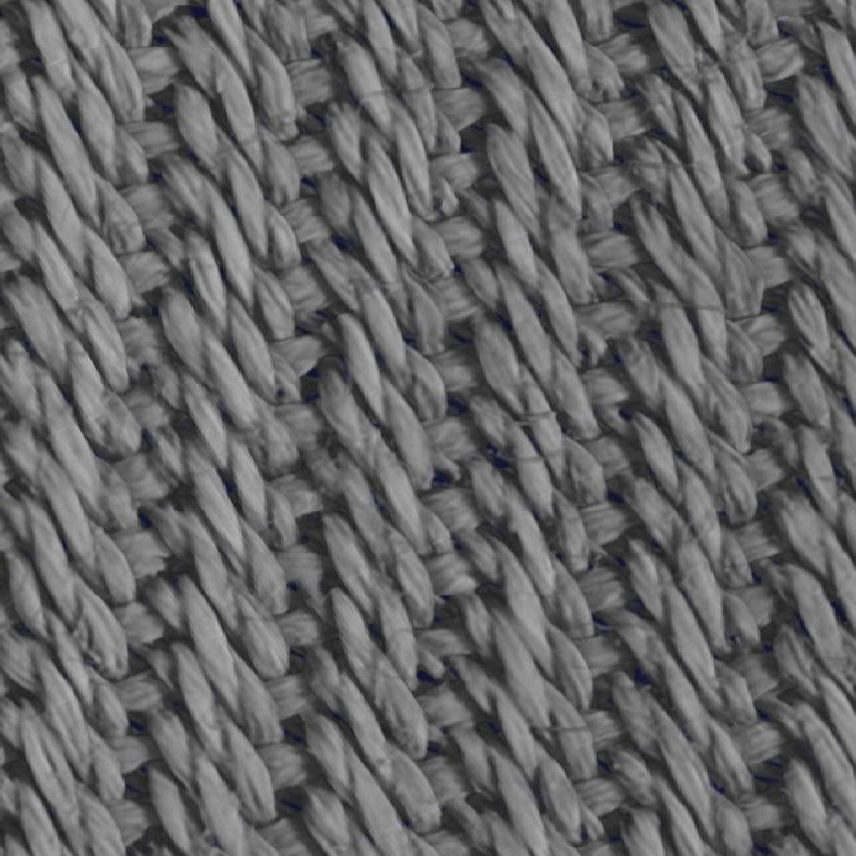

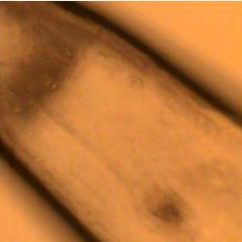

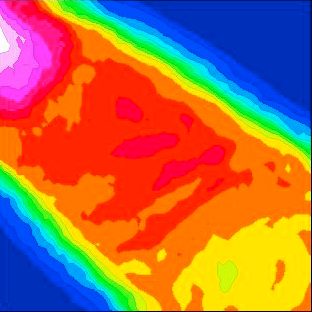

The imaging technique with μCT(computerized micro tomography) was used both to study in depth the morphology of the different tissues available for the realization of the coats, and to evaluate the welds with hot glue at the critical points of the sewing. The collaboration made it possible to choose fabrics that, at a morphological level, presented greater guarantees of resistance and ease of cleaning and improved the gluing process for sewing the coat.

Application on fabric

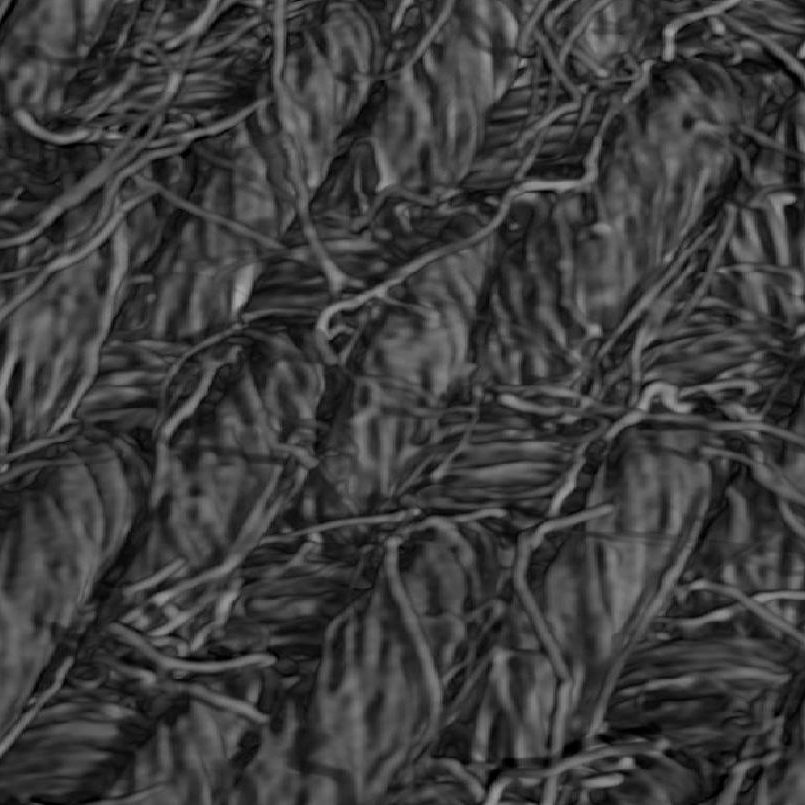

3D rendering of the fabric (voxel size 12.5 mm)

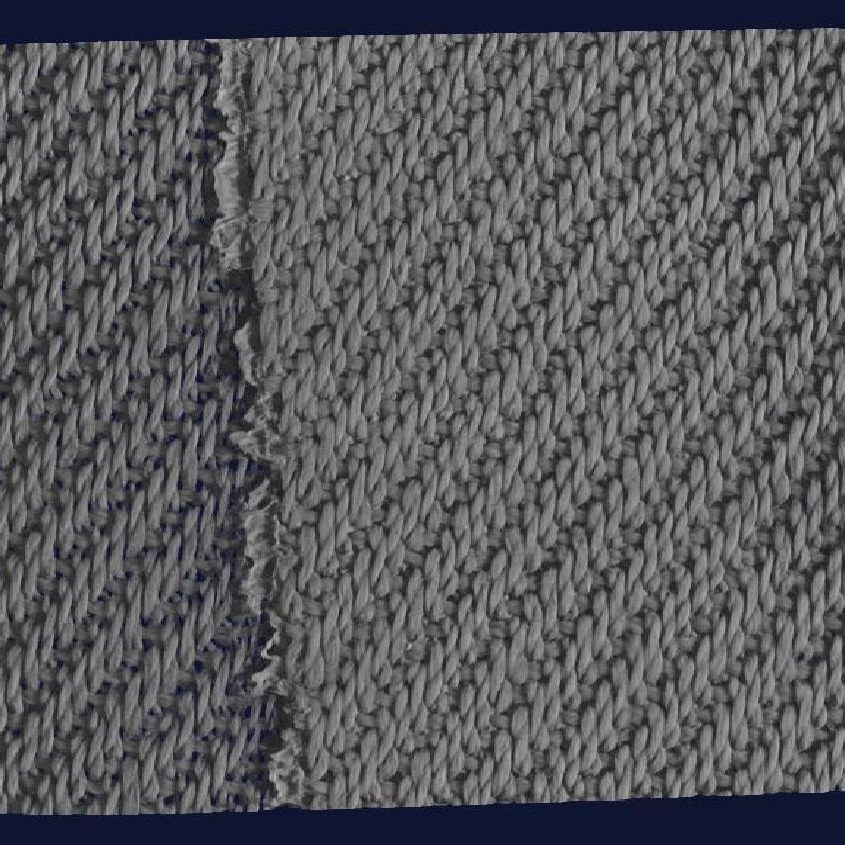

3D rendering of the Fabric (voxel size of 6,25 mm)

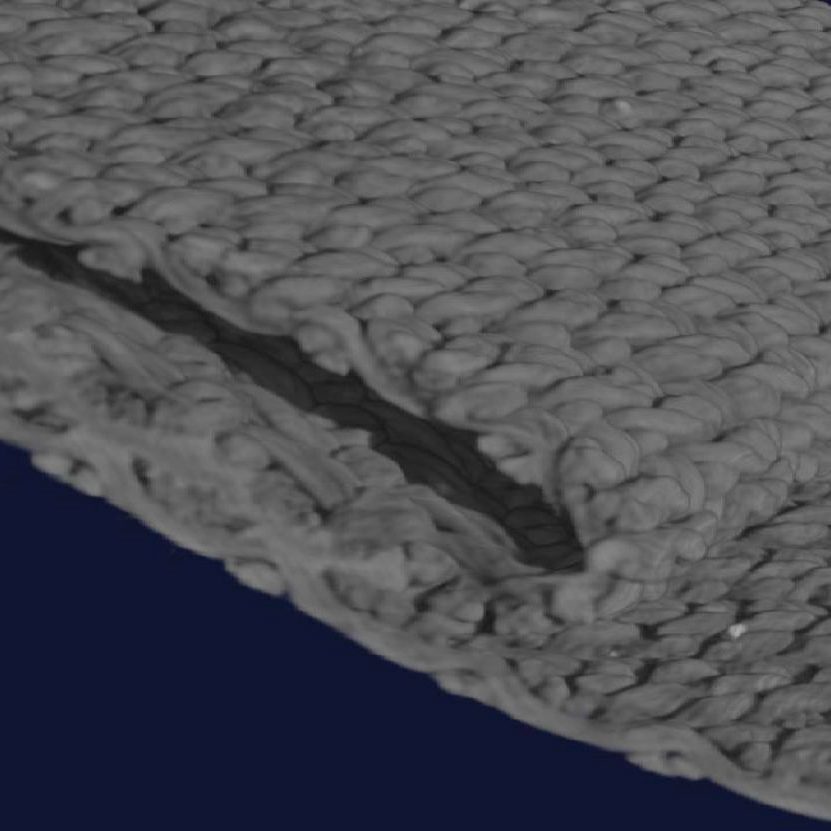

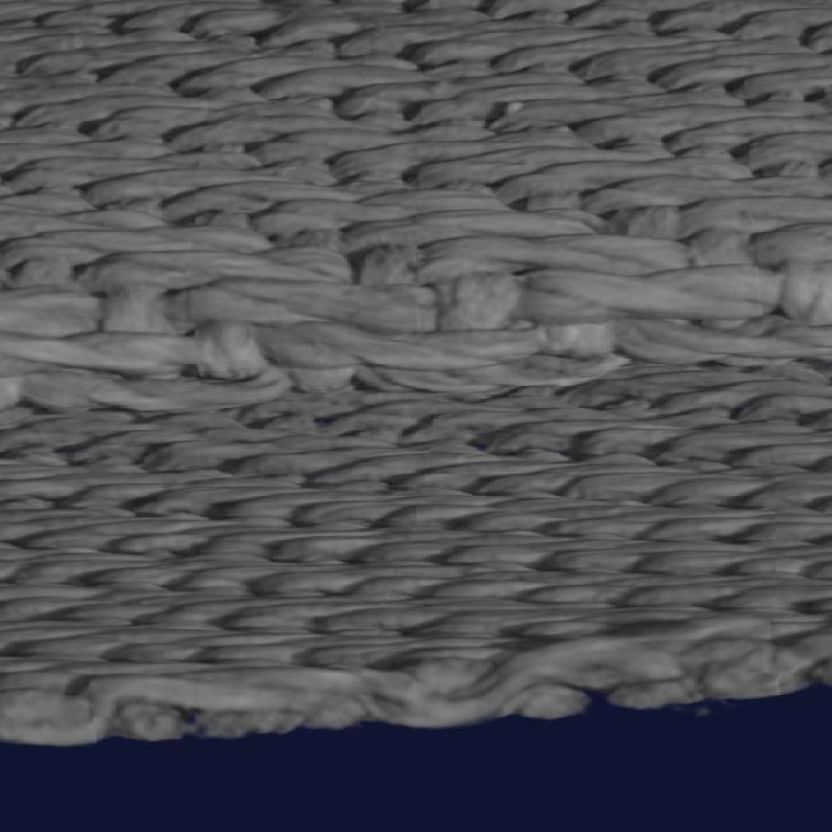

3D rendering of welded fabric (voxel size of 12.5 mm) and zoom of the areas of interest

Application of Infrared Techniques for the Study of Technical Textiles

New technical textiles are designed, developed and tuned to ensure the highest performance in the world of sports. They can be used in any season and in all weather conditions. New high-performance yarns, mostly based by polymeric composite materials need to be developed. Polymer defects introduced by spinning, such as yarn inclusions, or by coloring, may degrade both technical quality and attractive look of the clothes. In collaboration with two leading companies, the spinning and coloring process of several yarns have been studied using infrared techniques in the Mid-Infrared Region (MIR). Single filaments have been investigated with FTIR microscopy for revealing potential sources for yarn defects. In addition, all the chemicals used for coloring have been classified to create a reference database to be used in quality procedure checks to highlight potential variations leading to defect in coloring process. The collaboration has continued for two years in which sampling and measurement protocols for chemical products are developed to improve the company’s process control. In order to provide the company with full autonomy in carrying out its activities, the personnel involved have been provided with the appropriate training for the interpretation of the analytical data.

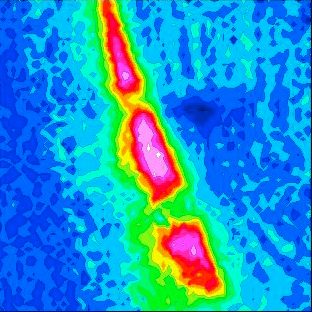

Yarn and tissue defects

Selected infrared spectral regions have been investigated to understand the nature of filament defects (diverse composition, polymerization degree, inclusions,…) and variability in coloring induced by of specific chemical products.

Experimental approach: Identify the defect by the visible part of the Vis-IR microscope, highlight the filament main component, isolate and chemically characterize the nature of the inclusions by selective chemical mapping.

THE LAB

ELETTRA SINCROTRONE TRIESTE

Elettra Sincrotrone Trieste participates to InCIMa4 projects with three laboratories focused on the techniques of X-ray Imaging and vibrational spectroscopies for chemical analysis.

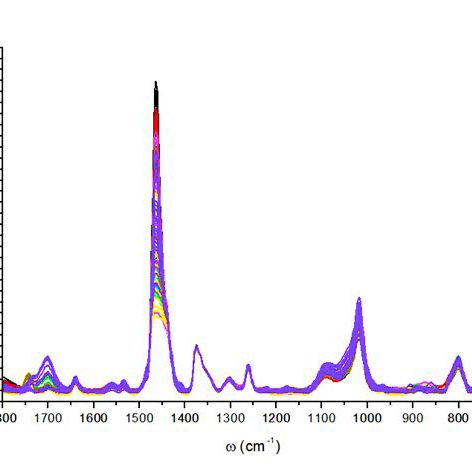

Application of Raman Spectroscopy in the study of nylon 6,6 relaxation process

Nylon is among the most important plastic material for engineering, such as for application as high-strength fiber or at elevated temperature as well as used for textiles and carpets, automotive parts and food packaging. Moreover, this semi- crystalline polymeric material has been widely studied with respect to thermal processes associated with its molecular structure, and therefore can be used as reference material.

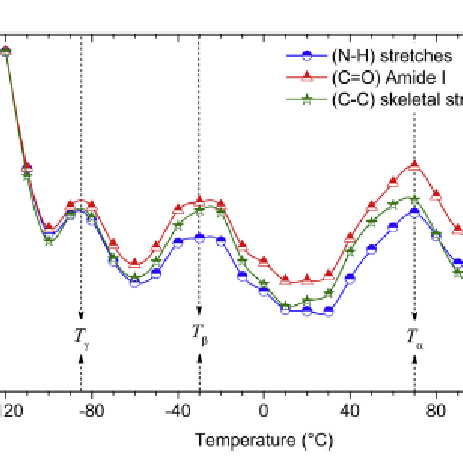

The characterization of polymers is highly important for the development of new polymeric materials, whereas the selection and design of new materials strongly depends on their thermal properties. In this study, Raman spectroscopy has been used to investigate the relaxation process of Nylon at specific temperatures (ranging from -120oC and 120oC) to demonstrate the validity of this technique compared with conventional techniques such as DSC, DRM, DMA and DMTA.

The results of the measurements with Raman spectroscopy showed temperature dependent changes for the three major relaxation processes, known as γ, β and α in a fashion quite similar to those obtained via macroscopic method for thermodynamic and mechanical quantities. In addition, the Raman scattering signal was able to deliver information directly from the source where these processes occur (molecular level) and the sample does not need to undergo any special chemical or physical pre-treatment.

[Ref: 10.1016/j.polymer.2016.10.058]

Product using Nylon 6,6

The figure shows the Raman peaks associated with different molecules and the three pronounced regions (T γ, T β ,Tα ) whose temperature range can be attributed, in order of increasing temperature, to the occurrence of γ, β and α relaxation processes

THE LAB

UNIVERSITY OF SALZBURG – Department of Chemistry and Physics of MaterialsRAMAN SPECTROSCOPY LAB

Raman spectroscopy is a non-destructive vibrational spectroscopic method based on the interaction of light with the electron shell.